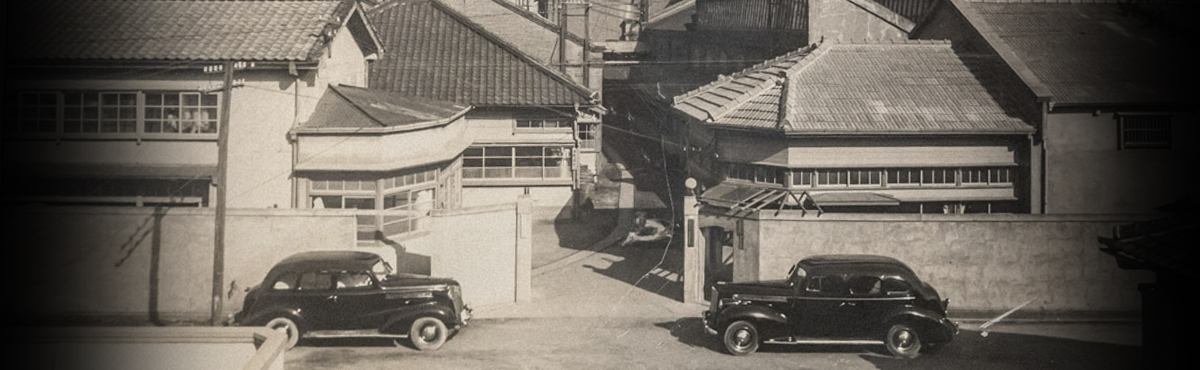

100 Years of Steadfast Devotion to Dyeing

Blessed with the bountiful nature of Wakayama,

our rich history will pave the way to the future. The next stage of textile printing awaits.

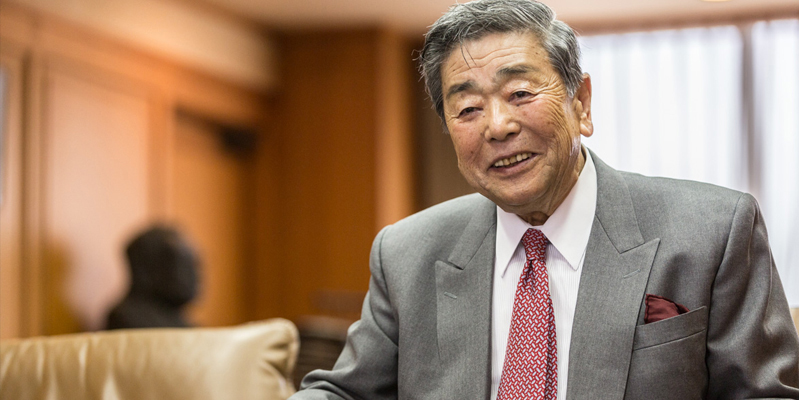

Overcoming Recessions with Our Accumulated Reliable Technology

Upon entering the textile printing industry, our main flannel printing operations took off to a great start and from the mid 1950’s overseas demand from locations such as Hong Kong, Singapore, Bangkok and America increased dramatically. While we kept continuously busy with the mass production of roller printed fabrics of synthetic fibers like nylons and acrylics, the dyeing industry underwent a sudden and drastic decline with the second oil shock in 1979. As the acting president at the time, I worked to realize the vision my predecessors had promoted “the power to look ahead” and changed our management strategy to one that created high added value by prioritizing domestic demand. By focusing on materials and improving the quality of existing products as well as making small lot production a reality, we were able to greatly increase the number of orders received from clients who recognized our technical skill and establish a business model based on commissioned processing. This I felt served as recognition of the efforts and achievements our company had made in its single-minded devotion to the promotion of the dyeing trade over the years.

A Management Philosophy of “Polished Expertise through Commissioned Processing”

We underwent a huge transformation as a company when we changed the focus of our management philosophy from the sale of original products to commissioned processing. This allowed us to develop the expertise needed to meet the requests of all types of businesses in the textile industry. After WWII, there was a rush to rebuild Japan’s economy due to a shortage of goods, and this led to a flood of businesses similar to ours within Wakayama Prefecture. Against this backdrop, we concentrated on extending our business not only for our mainstay, Kishu flannel, but also for fabrics such as printed cotton, down quilting, cotton sateen and silk, in order to create a solid presence in the industry. In particular, we were directly commissioned by major Japanese bedding businesses for our down quilting, with 70% of our profit at the time coming from bedding-related enterprises. During this period, we recognized the importance of further developing our technical skill and building trust with our customers in order to continue being selected from among our many rivals.

New Issues Arise

As we approach our 100th year, having already established routes for creating high added value and working to make contributions and develop technologies that are second-to-none, we at Wakayama Senko feel it is necessary to take our next leap forward. As part of this initiative, we participated for the first time in an exhibition in Tokyo. Here, we met customers who were trying to overturn conventional understandings of dye-processed products and create something completely original and unique. This experience reminded us that there is still much room for progress in this industry. Building upon the influence we have had up until now, we intend to take up challenges in new fields; and the strength of the projects and proposals we provide our customers will be essential to this. Putting effort into reforming and cultivating the thinking of our employees will surely be important as well. As our company’s dyeing technology pushed the industry forward in post-war Japan, we feel confident in its superiority.

The Future We Envision

for the Dyeing Industry

Thanks to Our History and Reliability

Working to always “stay half a step ahead of the competition,” we at Wakayama Senko have been at the forefront of the dyeing industry up until now. Carefully analyzing the movements of the world around us, we have continually considered what contributions we alone can make and carry out new challenges accordingly. However, the many years of economic recession in Japan have affected our business as well, and we feel it is time to come up with a new breakthrough. On this occasion, in addition to the spirit of “challenge” previously promoted, we have decided to put forth the concept of “trailblazing” in our effort to penetrate deeper into the dyeing industry. Equipped with 100 years of history and solid reliability and further increasing the design flexibility built up through our small lot production, we will aim to go “far beyond half a step ahead” and make sure to have fun along the way. To get started, along with achieving significant reductions to processes through the adoption of digital printing, we have also begun expanding our product lineup into fashion and other industries outside of bedding and iniatiated ventures into new, unprecedented arenas. It will be important from here on not only to have exceptional technology but also the exceptional human sensibility to support it. We feel the essence of craftsmanship lies in incorporating the ideas and thoughts of the people using what is produced. Always adapting to the changes of each generation, we at Wakayama Senko will work to continually to pursue genuine craftsmanship.

Aiming to be a company the world trusts and celebrates, we will continually challege ourselves with developing new products.

Since our founding in 1907, we at Wakayama Senko have devoted ourselves to the dyeing trade and carried an undefeatable spirit that helped us overcome the postwar years. Ever sensitive to the trends of the world around us, we continue today to pursue those things we alone can deliver. We place the utmost confidence in the artisinal technology that has been passed down since our founding. This technology is not simply related to the processes of dyeing but also includes the artisinal sensibilities we have inherited over the years. With “technology” and “artisinal sensibilities” as our most prominent strengths,we have recently begun expanding our product lineup and initiated endeavors into fields uncharted for us, such as fashion, product design and planning. With the adoption of digital printing, we have also been able to achieve great reductions in the time required for product delivery. In these ever-changing times, we promise to keep moving forward in order to become a company essential to society that brings forth new possibilities for the dyeing industry.

President Yoshihiro Takagaki